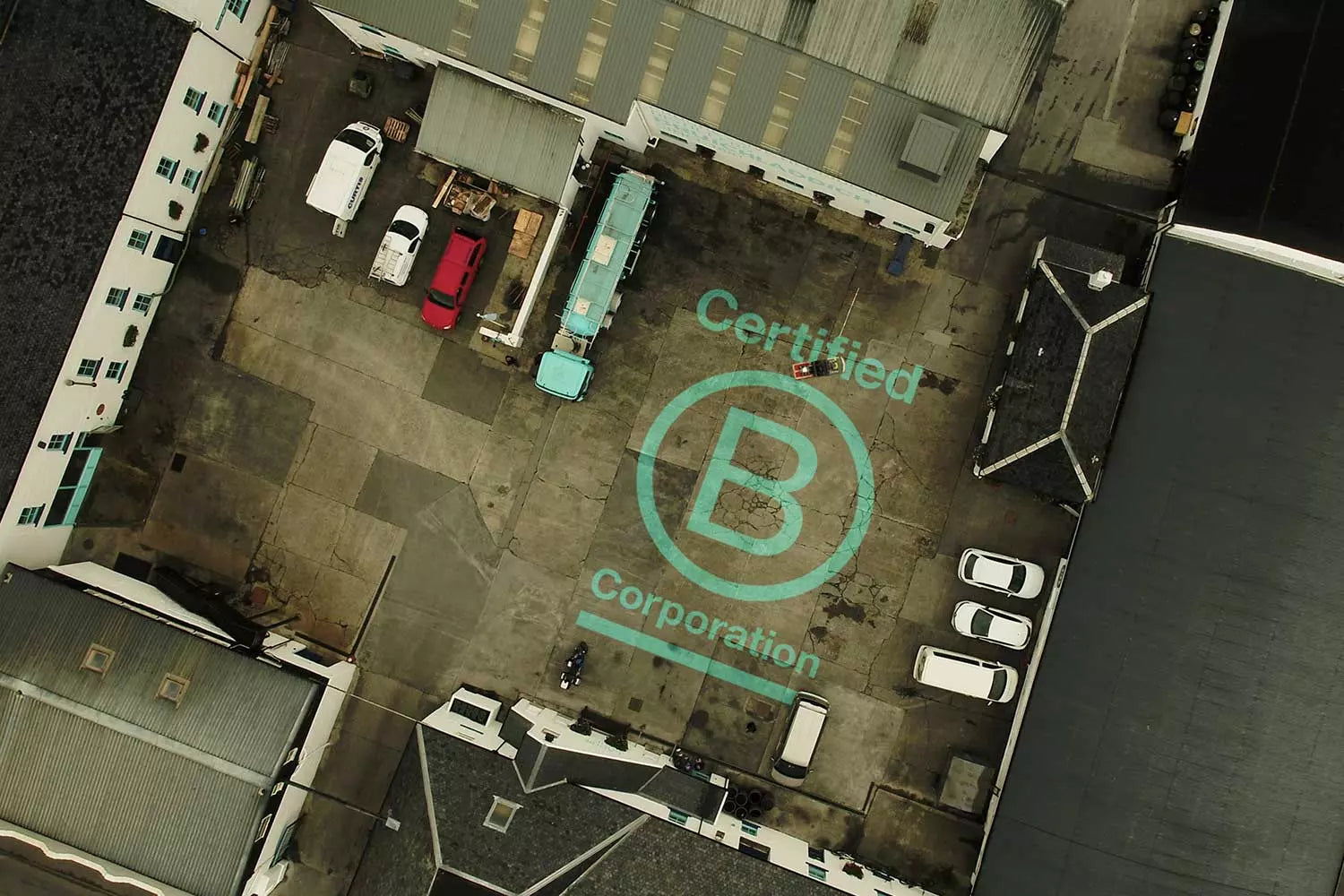

BRUICHLADDICH IS B CORP CERTIFIED

- 3 mins

As of Tuesday 19th May 2020, the date we officially became B Corp certified, we joined a change-making community of 3,327 companies, in 150 industries, across 71 countries. The B Corp movement is gathering momentum - by the Summer of 2022, more than 5,200 businesses, in more than 80 countries had committed to it and made the grade - but what is it? What is it trying to do? And why does it mean something to Bruichladdich Distillery?

Set up in 2006, the B Corp certification process was organised to help mission-driven businesses protect and improve their positive impact over time. Acknowledging that governments and non-profits can only go so far in driving change, we stand together with for-profit businesses that balance profit and purpose, helping to tackle some of the challenges our modern societies face.

Perhaps the B Corp logo is familiar to you from other arenas; it’s still uncommon in the spirits industry. There are only a dozen distilleries globally that have achieved the status, some making vodka or rum, others limoncello or gin. We are the only whisky and gin distillery in Europe to meet the stringent standards of social and environmental performance, accountability and transparency; it took us over a year to complete the detailed submission process. Nc'Nean on the Scottish Mainland and Headframe Spirits, based in the USA, are the only other distillers of whisky in the B Corp directory – so we’re in brilliant company, with room for many more.

Highlights that helped us to achieve our original certification included our benefits package to staff. These include Living Wage employment, a 5-10% bonus scheme shared for 100% of our staff, annual cost of living adjustments as well we private healthcare, life assurance provisions and 34 days paid annual leave as standard. We’re also a diverse employer with a sound training and development program. Our team in 2020 had 50%+ female senior management and an age range of staff spanning from 19 to 75 years of age.

Our progressive attitude towards our community and sustainability also helped us qualify. We circulate the wastewater from our stills to heat our offices, bottling hall and visitor centre. We switched to 100% green electricity, sourced within the UK. We have ambitious plans for the future, and we can confidently say we are on our way.