SUSTAINABILITY

WE HAVE A LONG-TERM VISION TO BE MORE SUSTAINABLE IN ALL WE DO

WHAT DOES SUSTAINABILITY MEAN TO US?

We are working to reduce the impact of our operations and become more environmental in our actions, all with a heightened sensitivity to growing within our island home.

We must ensure our impact is positive, and that we continue to improve the quality of life for our planet and our people. Only with a clear vision, holistic approach and a solid foundation, will future generations be inspired to take over as custodians.

Our distillery is home to four unique spirits; Bruichladdich, Port Charlotte and Octomore single malt whiskies and The Botanist Islay dry gin.

Here we outline our ambitions under four key pillars of sustainability; Agriculture & Biodiversity, Packaging & Waste, Islay & Community, and Energy.

ENERGY

We are reducing our carbon emissions and introducing greener sources of energy where possible. Ultimately, our ambition is to decarbonise distillation by 2025.

AGRICULTURE & BIODIVERSITY

We will continue our research into sustainable agriculture, exploring the models necessary to make our plans viable. We will be traceable and transparent and continue our progressive approach to growing and buying barley.

LEARN MORE

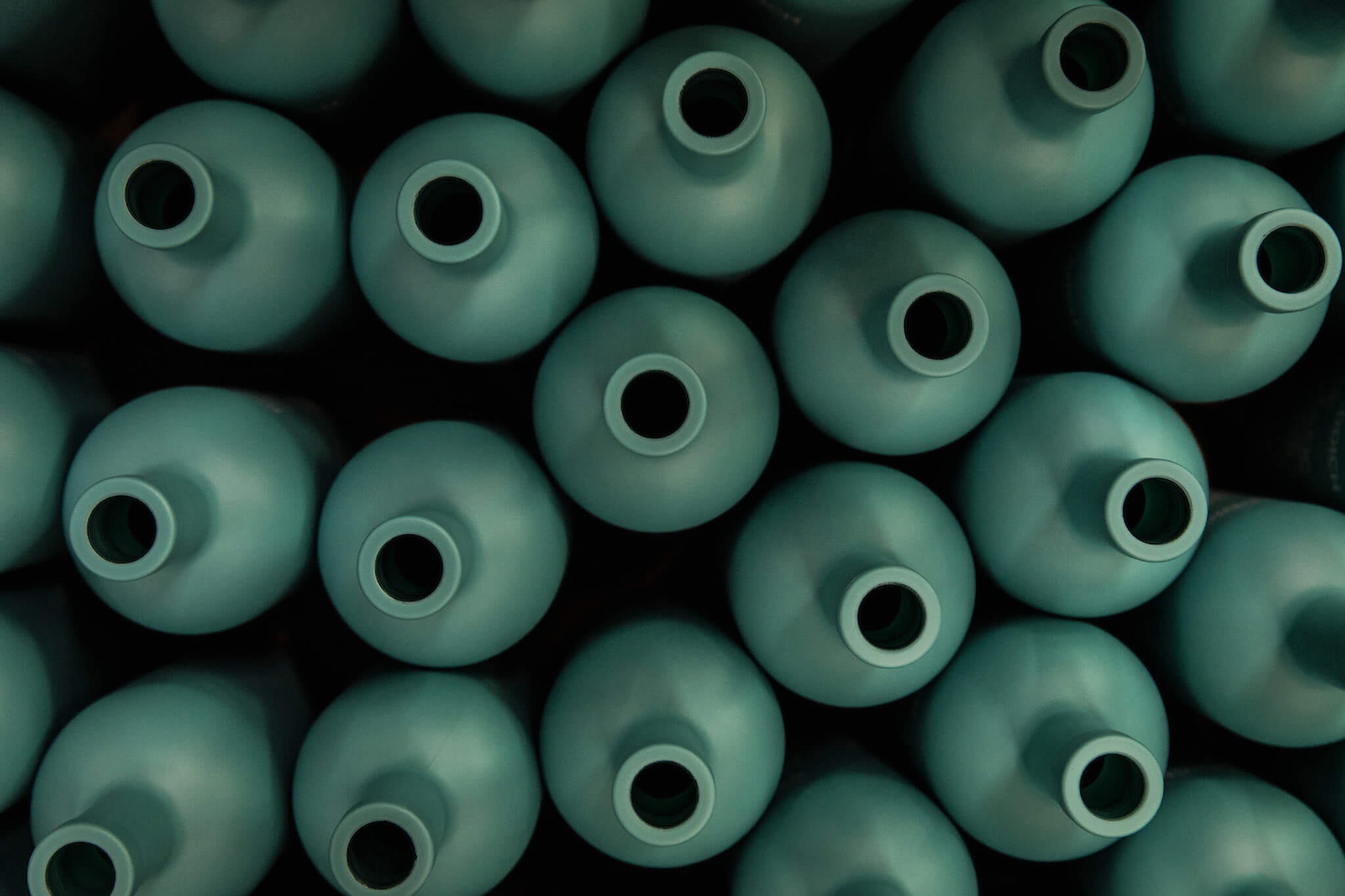

PACKAGING & WASTE

We are on a mission to use less and use better. From production to packaging, we will reduce our impact and waste.

ISLAY & COMMUNITY

Our social, economic and environmental impact on the island must be a positive one. Our community on Islay will continue to be a the heart of every decision we make and we are passionate about leaving a lasting legacy on the island and beyond.

LEARN MORE